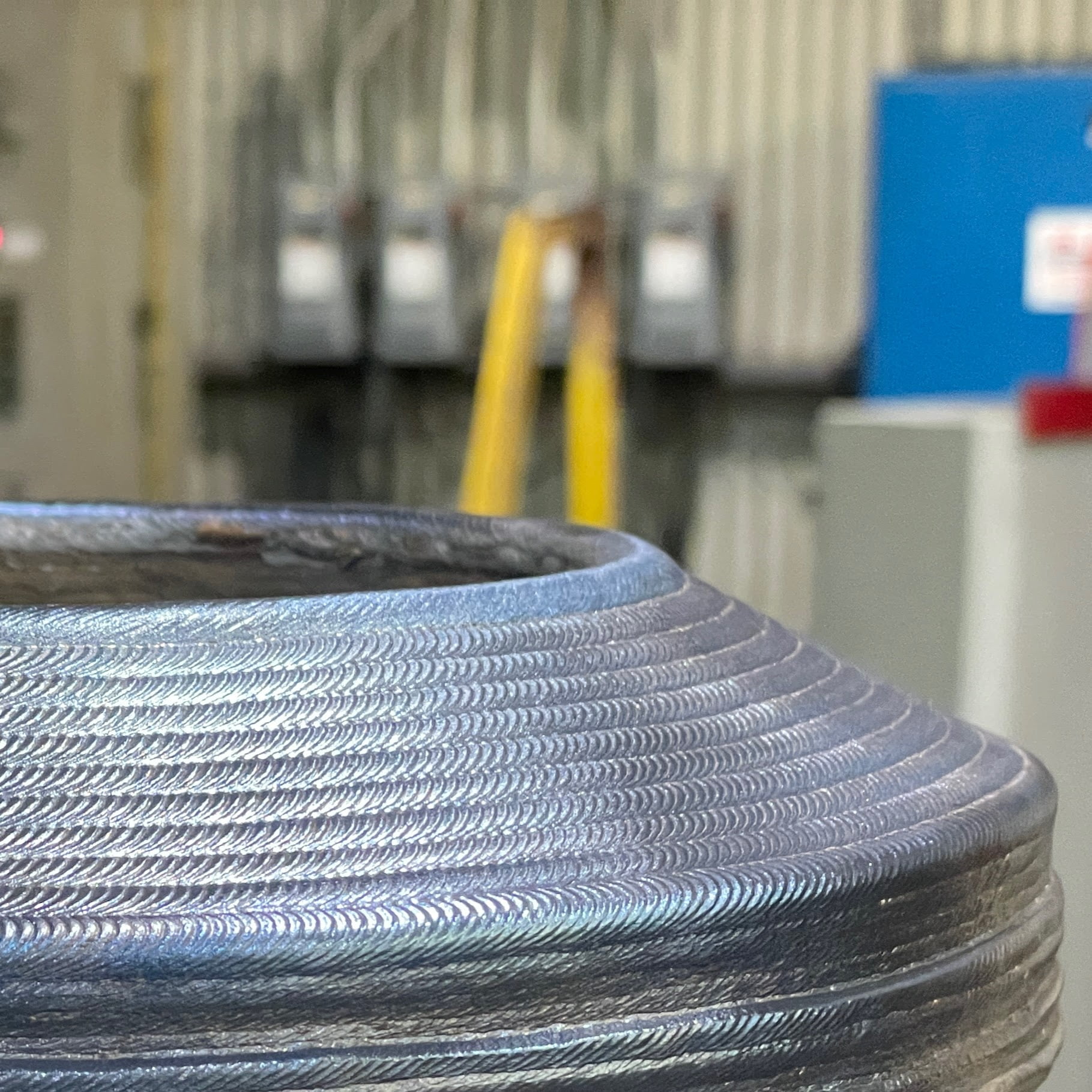

Weld Overlay

THE 1-2-3 OF WELD OVERLAYS

Weld overlay is a method to add a protective layer to a metal surface. In simple terms, it’s like giving a metal object a strong and durable coating that increases its lifespan. This extends a part’s service life, protects the environment, and helps reduce lifecycle costs. Weld Overlays are used in industries where surfaces undergo significant stress or environmental challenges.

Here’s How It Works:

Welding Method, GTAW-P Hotwire:

Gas Tungsten Arc Welding, or GTAW is a welding process that forms an electric arc between a tungsten electrode and the base metal being welded. The electric current is Pulsed, rhymically increasing and decreasing amps to limit how deep the weld penetrates into the base metal. The welding wire is preheated to make the welding faster, e.g. increase deposition rate.

Protective Layer:

The purpose of weld overlay is to create a protective layer on the metal that prevents wear, corrosion, galling or other forms of damage.

Precision:

The pulsing feature allows for more control over the welding process. It lets the welder adjust the heat input and quality of the protective material with greater precision.

In a nutshell, GTAW Hot Wire Hotwire is a cladding technique that adds a tough layer to metal surfaces, making metals more resistant to wear and corrosion through welding.

Weld Overlay is synonymous with cladding. Weld overlay layers the surface of a metal to protect it from corrosion, abrasion and prevent wear. Alloys like Inconel, Stellite, Stainless Steel, and even Hastelloy are on a metal part, producing sealing surfaces, permanently sealing machined features and quick connections and autoclave ports. Ideal for making corrosion resistant and leak-proof seals for sensors, flowlines and male-female pipe sealing connectors